ARCO's Tech Tip on Starter Failure

WE COULD TELL YOU WHY YOUR STARTER FAILED, BUT WE THOUGHT YOU MIGHT LIKE TO SEE FOR YOURSELF.

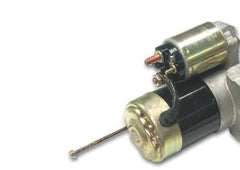

Although the outside of the starter (on left) looks fine, the flywheel picked up water from the bilge and pumped it inside the starter causing the corrosion shown here.

WATER INTRUSION IS THE #1 CAUSE OF STARTER FAILURE.

If water gets pumped into the motor portion of the starter from the flywheel, it will not drain out. As you can see, rust and corrosion will destroy the inside components of the starter.

THE #2 CAUSE OF STARTER FAILURE IS WATER INGESTED INTO THE ENGINE.

DON'T BE FOOLED BY OUTWARD APPEARANCES.

As shown here, the outside condition of the starter appears to be fine, but by removing and inspecting the lower starter case bolt, it is obvious water has gotten inside the starter.

Shown here are damaged starter mounting pads. Water ingested into the engine stresses the mounting bolts beyond normal conditions. The bolts stretch and cause the starter to become loose. This could eventually lead to damage to the ring gear, starter casting and possibly the entire engine block.

Download the full Tech Tip sheet HERE, or visit our Tech Tips Landing Page HERE.

You can also visit our YouTube channel for more useful information