The Power of True 24V and 48V Performance: A Story of Efficiency and Reliability

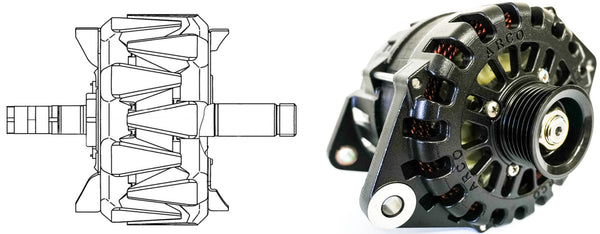

In the demanding world of marine and RV power systems, efficiency, reliability, and longevity are non-negotiable. At the heart of these systems lies a critical component: the alternator. While many manufacturers claim to produce high-output 24V and 48V alternators, a closer look reveals a crucial difference that sets ARCO apart—a true 24V rotor for a 24V alternator and 48V rotor for a 48V alternator.

The Hidden Flaw in the Competition

Many competing alternators marketed as 24V and 48V units are built using rotors originally designed for 12V applications. At first glance, this approach might seem practical, but it introduces a cascade of inefficiencies and risks. When a 12V rotor is forced to operate in a 24V or 48V system, it demands aggressive field current reductions—sometimes by as much as 78%—just to prevent overloading. This artificial limitation restricts the alternator’s output potential at all RPMs, reducing its overall performance and efficiency.

The Efficiency Advantage of a True 24V and 48V Rotor

ARCO takes a different approach. By utilizing a native 24V or 48V rotor (depending on whether a 24V or 48V alternator is used), ARCO alternators operate with the field current properly matched to the system’s voltage requirements. This design choice results in several key advantages:

1. Higher Efficiency at All Speeds

-

By using a 12V rotor, the competition is losing out on the efficiencies inherent in a higher voltage/lower current design. This translates directly into lower temperatures and greater efficiencies when using a native field current in our 24v and 48v alternators.

-

A true 24V and 48V rotor allows the alternator to generate optimal power at all RPMs without excessive current restrictions.

- This leads to consistent, high-output performance without artificial limitations.

2. Lower Operating Temperatures

- Because the regulator works on a lower field current, the alternator runs cooler.

- Cooler operation reduces thermal stress on internal components, extending the lifespan of the unit.

3. Enhanced System Safety and Reliability

- Using a mismatched 12V rotor in a 24V and 48V system risks severe damage if the external regulator fails to properly reduce field current.

- A native 24V and 48V rotor eliminates this risk, ensuring stable and reliable performance in even the most demanding conditions.

Real-World Impact: A Case Study

Consider a fleet of commercial fishing vessels or ambulances with high-output alternators to power critical navigation and communication equipment. When tested side by side, vessels/vehicles using competitors’ 24V alternators—built with 12V rotors—experienced frequent overheating and output drops at low RPMs. In contrast, vessels equipped with ARCO’s native 24V alternators maintained steady power, ran cooler, and required less maintenance over time.

The Clear Choice for Performance and Longevity

The difference is clear: ARCO’s commitment to true 24V and 48V rotor technology results in a more efficient, powerful, and reliable alternator. Whether for marine, RV and caravan or commercial/professional applications, choosing an alternator designed from the ground up for 24V and 48V operation ensures maximum performance, longevity, and safety.

When efficiency and reliability matter, trust the power of a true 24V and 48V alternator. Trust ARCO.